By Matt Mohler, CSHM

8/22/24

What is Safety in Action? It is the actions taken by a company, their leadership, safety committee and safety champion to enhance, promote and ensure safety for every person within the organization.

Safety in Action includes compliance with all standards, federal and local, and unique plans, programs and policies for the industry or company. Then performing to those standards and policies with enthusiasm and dedication to an end goal; no harm from work.

We need to believe and strive to the idea that no one should be expected to endure harm, no matter how minor. We should inspect, audit and train to prevent all hazards in the hopes that we avoid even a minor incident, such as a splinter. If we can adjust our focus to drill down to preventing bumps, bruises and splinters AND we don’t loose sight of the major hazards present that we have already locked down, then we should be able to move forward to no harm.

Imagine a safety culture where employees feel safe knowing there is an active emphasis on safety. Where they either participate or see an active safety team or committee always on the lookout for hazards and working to control risks. A company that conducts regular monthly safety trainings on the topics that affect workers and workplaces every day. You may not think it but employees who grumble about having to go to another safety training, are also feeling that the company cares, or the safety team or champion cares, if done properly.

Safety in Actions means conducting regular training. I believe at a minimum monthly. A good training can be conducted in thirty minutes, that’s only six hours per year. Don’t just do a lame training or outdated video to check the box. Make sure the training is meaningful, useful and up to date. Although some trainings are not required by OSHA to be conducted annually, you may feel topics like lockout and hazard communication do, so why not refresh your workforce more often. Repetition is the best teacher. Engage your workers, change up the message from year to year on repeat trainings, don’t show the same safety video for ten years straight. Mix in some humor, tells stories, show statistics, give real life examples and as a presenter, share your own experiences. Sometimes the why is just as powerful as the reason.

Perform safety audits and inspections looking for weaknesses and opportunities to improve. Bring in a fresh set of eyes from within your workforce, your network of other safety champions and organizations life Safety & Hygiene to spot things that you have become blind to because you see it every day. While performing audits and inspections within an area of your workplace, talk to the workers and leadership in the area, as long as it is safe to distract them. Listen to their thoughts, concerns, complaints, sarcasms and hear the message they are trying to share with you that may prevent an injury or present an opportunity for improvement. Look for work-arounds that they have created and try to understand why they felt the need for the work around and also explain why it may not be the best or safest way or action. If necessary, shut down the production if you find an unsafe condition. Safety in Action sometimes means making decisions and taking actions to protect the workforce that may not be popular with production leadership. You know what else is not popular, knowing and looking the other way and a worker is harmed. How much longer will production be interrupted now? Will there be fines? Will there be a somber message to workers families?

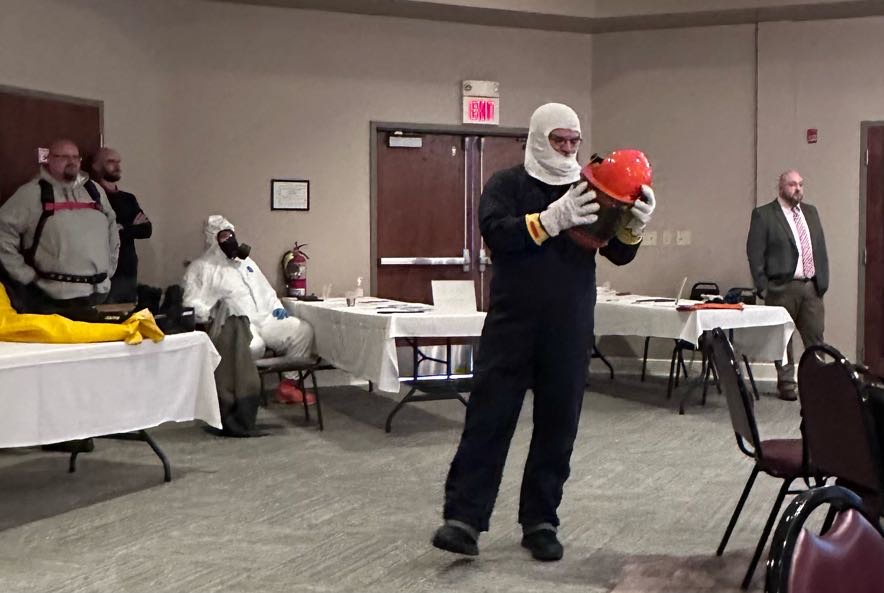

Safety in Action is what builds a positive safety culture. Every workplace has a safety culture, the question is, are you proud of it? Does your workforce believe you care more about them then you do about profits? We must have profits, a company will not survive if it does not make money and cover the overhead, but at what cost? Blood, sweat and tears is what built this country and many of the business that we see today. The blood is what built safety standards, OSHA, EPA, DOT, PHSMA, RIA, NIOSH and all the rest, unfortunately have many standards as a result of spilled blood from a harmful accident on the job. We need to encourage the hard work necessary to be successful, wish for tears of joy and not sorrow and avoid spilling blood for the sake of making profits. Ensure workers know it is acceptable to spend more time to perform tasks safely, with the correct tools and equipment. Short-cutting is not an acceptable option. Safety in Action, a positive safety culture and buy in from the workforce can be summed up from another old adage; “workers do not care how much you know, until they know how much you care”. Company leadership, safety teams and especially the Safety Champion, you must be unwavering in supporting the safety message, plans, procedures, programs and policies. You can never cheat for even a second without losing the trust and respect of those you are working to inspire to keep safety in-mind each day. If personal protective equipment is required for them, it is required for you, the CEO and/or owner. Each of you are able to be harmed equally.

Have fun with safety. Participate in National Safety Month and OSHA Safe + Sound week or any other programs, create your own fun safety day! Encourage participation and feedback. If you have a suggestion box that is full of dust instead of safety suggestions spend some time during one of the aforementioned events to conduct a suggestions blitz. During Safe + Sound week in 2018 we held a suggestion blitz on each shift, and spoke with every employee of the company. We logged each suggestion and tracked the actions from each. We collected more than 110 suggestions from the blitz. Roughly eighty resulted in some level of safety improvement. That is Safety in Action! Sometimes you have to draw the information from your workforce. If you take the time to meet with them, you may be surprised at what you learn.

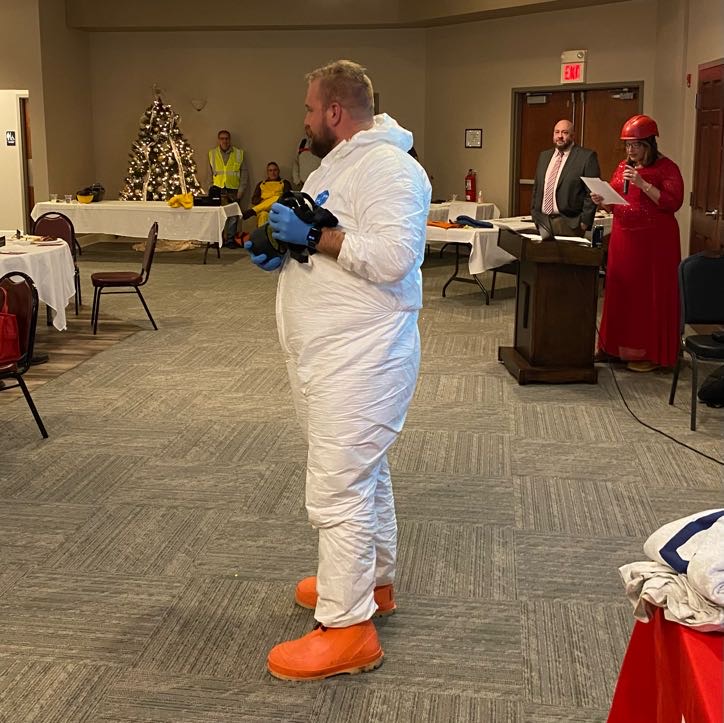

Collect data to know how your company is performing on required programs. Have noise levels monitored to ensure you know if you need to develop a hearing conservation plan. Test the air to know that you have good indoor air quality or if you need to develop a respirator program. Be sure the workforce is aware of the monitoring and share the results. If results are not good, don’t try to hide it. Communicate with your workers what the next steps will be, which will include training as you follow the federal standards. When PPE is required, don’t assume you can pick what is best for them. When there are options, include the workers that will have to don and doff, care and maintain the equipment. If they want tie-dye ear plugs instead of green, who cares! Get the tie-dye ones.

Promote the success of your safety programs. Celebrate with the entire workforce any awards or compliments received regarding the safety at your workplace. Recognize employees who offer suggestions and consider developing a Safety Suggestion of the Year award! This may entice others to participate in offering suggestions. Reward those who provide information that corrected a safety issue or likely prevented a future incident. All of this provides awareness and acceptance of Safety in Action. Let all who work here know, safety does matter! We expect everyone to go home in the same condition, or better, then when they arrived for work today. I was challenged once on that last sentence on the “or better” part. How can we make someone better when they leave at the end of their shift? My answer was simple. Did we provide good training? Did we provide healthy insights? Did we include information in training that can be used away from the workplace as well as at the workplace? Did we explain and provide tools to help them in their daily lives? Stress relief, distracting driving information, health screenings? Our safety program should also help to develop the person, not just the worker. We must realize that many will not continue on with education. We may be the only source of new information and education they receive after high school. Unless you count online information, and we all know if was found on the internet it must be true, right! LOL, NO! Most Safety professionals use these three letter EHS in their title, but often forget about the H – HEALTH. Be sure to include health training beyond PPE and needs to be complaint at the worksite. When is the last time you shared information with employees regarding mental health and outreach opportunities available in the local community? Many companies provide an Employee Assistance Program (EAP). How many have shared information about it, other than mentioning it as part of new hire orientation? The health component goes towards showing you care about the worker and they are not just a number needed to keep production running.

I hope you are getting the message about Safety in Action. Doing what is expected for compliance and beyond, actually caring about the workforce and not going through the motions and including and engaging the workers to participate and support your safety programs. By doing this companies and safety personnel will see safety culture improve. You will have workers asking safety questions before just doing something and hoping nothing bad happens. Leadership will look to include the safety team on new products, work cells and equipment at the beginning to ensure safety and compliance concerns are addressed early rather than reacting once the hazard is on the job site. In short, you will see a safety culture that the company and workers are proud of and can work together to continuously improve.

ABOUT THE WRITER: Matt Mohler is the Director of Facilities/EHS&S at Delta Systems, Inc., in Streetsboro. He currently serves as the Chair of Portage County Local Emergency Planning Committee working towards EPCRA compliance for reporting companies within Portage County. He is a U.S. Navy veteran and a Certified Safety and Health Manager (CSHM) through the Institute of Hazardous Materials Management (IHMM).

You must be logged in to post a comment.